Introduction

What is VFD?

VFDs are a very important part of the industry. There are many reasons why VFD is used in industries in this post I will share What is VFD? |Top VFD Manufacturers | VFD Buying guide

VFD is not only used for industrial applications but is also used in commercial applications like lift systems and many more.

Before we learn about VFDs, first we discuss how to control AC motor speed using different methods and when we need VFD for our application.

Induction motor is most commonly used in industry, speed control of induction motor is very important in the industry.

in rated speed operations there is no need to install VFD. Only soft starters are working fine for rated speed. But for variable speed control applications VFDs are required for better control and energy saving.

An example of a variable speed application is the HVAC system. According to inlet fluid temperature HVAC fans speed is controlled using VFD as you can see in this image.

Basic Structure of VFD: –

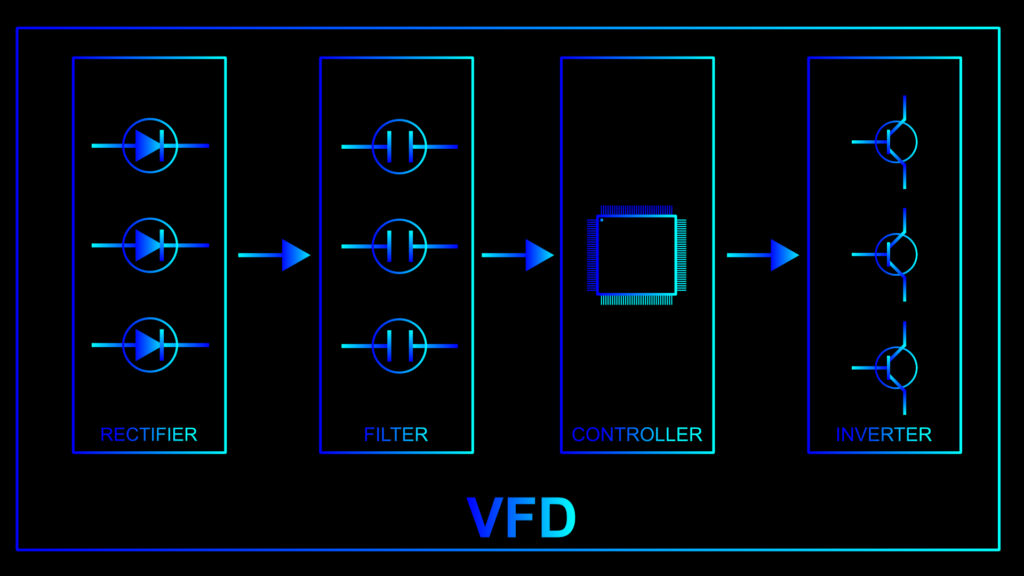

VFD is made of four basic components for doing their jobs.

- Rectifier system

- Filtration system

- Inverter system

- Controller

The rectifier is responsible for converting AC supply into pulsating DC supply. After the filtration stage pulsating DC converts into smooth DC voltage.

The controller is doing rhythmic switching of the thyristor in the inverter section so it is converting DC voltage into AC voltage.

Types of Drivers: –

- AC

- DC

- Servo

Top VFD Manufacturers

| No | Companies |

|---|---|

| 1 | ABB |

| 2 | Danfoss |

| 3 | Delta |

| 4 | Siemens |

| 5 | Mitsubishi |

| 6 | Yaskawa |

| 7 | Galt |

| 8 | Hitachi |

| 9 | Allan Bradley By Rockwell |

| 10 | Schneider Electric |

| 11 | Control Technique |

| 12 | Weg |

| 13 | EATON |

| 14 | inverte |

| 15 | Toshiba |

| 16 | TMEIC |

| 17 | LS Drives |

| 18 | Fuji Electric |

Financial Analysis of Global VFD Market

The global VFD market in 2020 is around 19.2 billion Dollars 💵 and it will be estimated to reach up to 24.3 Billion Dollars in 2025.

The estimated Price range of different VFDs

| No | Company | Power Range | Price |

|---|---|---|---|

| 1 | ABB | 1.5HP-25HP | 450$-2800$ |

| 2 | Danfoss | 2HP-25HP | 370$-2300$ |

| 3 | Delta | 2HP-20HP | 290$-1700$ |

| 4 | Siemens | 1.5HP-214HP | 600$-21000$ |

| 5 | Mitsubishi | 2HP-40HP | 1000$-5800$ |

| 6 | Yaskawa | 1HP-40HP | 270$-4300$ |

| 7 | Galt | 0.5HP-700HP | 120$-27314$ |

| 8 | Hitachi | 1.5HP-500HP | 235$-25152$ |

| 9 | Allan Bradley | 0.5HP-600HP | 350$-81285$ |

| 10 | Schneider Electric | 0.5HP-700HP | 230$-153813$ |

| 11 | Control Technique | 1.1HP-11HP | 530$-2200$ |

| 12 | Weg | 1.5HP-175HP | 780$-14720$ |

| 13 | EATON | 3HP-75HP | 600$-6830$ |

| 14 | INVERTEK | 0.5HP-250HP | 183$-10325$ |

| 15 | Toshiba | 1HP-5000HP | 600$-411300$ |

| 16 | LS Drive | 3HP-15HP | 180$-400$ |

VFD Buying guide

The VFD selection process is very important for your industrial and commercial applications. Choosing the right VFD for your application gives you economical and functional benefits for your industrial application.

When you go to buy VFD for your application there are many factors that you have to consider before you buy VFD.

Before you go deeper buy any VFD first gather information about your motor and system information it will help you to buy the proper VFD for your application.

This is the list of selection guidelines: –

- Motor Output Power

- Voltage Rating

- Maximum Current Rating

- Onboard communication

- Environment Conditions

- I/O connections availability

- RPM

- Type of loads

- Overload Rating

Motor Output Power

The size of VFD depends on the full load Application of the Motor to be controlled. The selection of VFD is according to the Full Load horsepower of the motor.

Voltage Rating

According to voltage rating VFDs are divided into two parts

- Small Voltage Drive

- Medium Voltage Drive

Maximum Current Rating

According to the Full load, the current value VFD is selected. The current rating always comes with two values. The first is Normal operation Current and overload current capacity.

Onboard communication availability

Communication is also an important part of the VFD selection process because in the industry all VFDs are connected with PLC using one communication protocol like ProfiNet, Profibus, Ethernet, and Modbus.

If you want to upgrade your plant in the future with other automation vendors, these guidelines will help you.

I/O Connection Availability

Modern VFDs also come with extra multifunction analog and digital I/O functionality, by programming this I/O you will be able to enable multitasking using VFD.1

RPM

RPM of the motor is also very important to take into consideration because motors are generally not all allowed to run less than 20% of their rated speed.

Type of Load

The VFD selection process also depends on what type of load it is. Reference of the Load generally two types of Loads we see in the application

- Constant Torque Load

- Variable Torque Load

Overload Rating

Overload Rating is very important for VFD selection Because sometimes in the industry there is a need to run the motor in an overload condition. That’s why some industries prefer VFD with High overload capacity.

Resources

1. VFDs.COM

About VFDs.com

VFDs.com is a division of Energy Management Corporation. With over 2,000 drives in stock and ready to ship, we have one of the largest Variable Frequency Drive inventories in the United States.

EndNote: –

This is a brief introduction to VFDs. I hope you find something new about VFDs and the global VFD market for industrial automation.

I am also trying to make other posts on this topic, if you want then comment below. If you find this post interesting then also check our latest post on OPC-UA.