Introduction: –

In this article, I will give you some basic knowledge about MES (Manufacturing Execution System) software used in the industry.

MES software is used in higher-level industrial automation for the execution of operations and has improved the production output of the company.

MES software is company-level software that manages and displays an overview of plant performance and execution of different processes. MES software plays an important role in a plant company’s ERP (Enterprise Resource Planning) Planning.

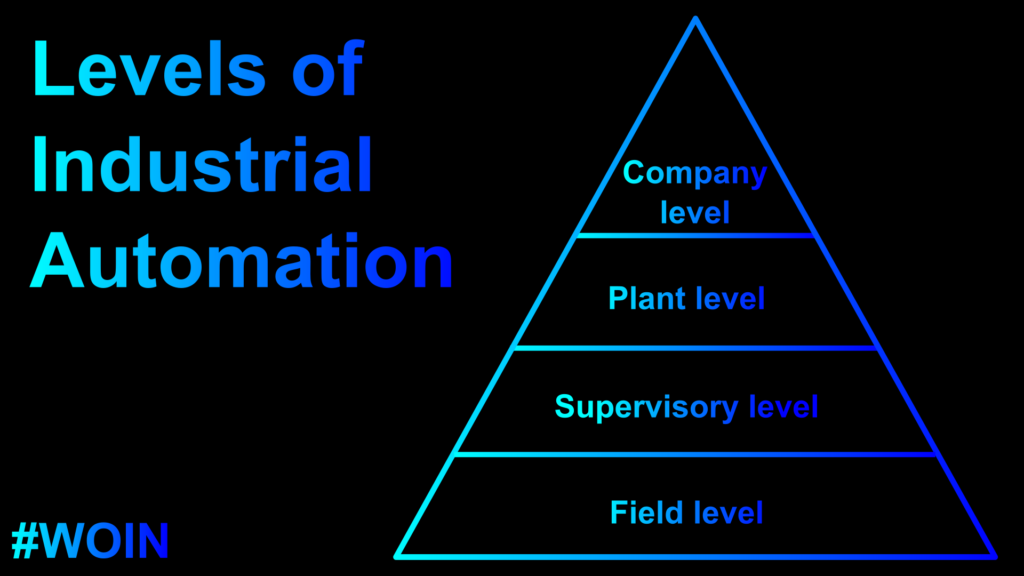

But before we start to learn about MES software we have to learn about the levels of automation in the industry.

for easy understanding, I made this Vector graphic. Let’s talk about levels of industrial automation.

Types of levels in industrial automation: –

- Company level

- Plant level

- supervisory level

- Field Level

The company level is also called the Enterprise level. It all starts with the execution of the command given at the company level transferred to the Plant level then the supervisory level and finally command reaches the field level.

Now all data from the field level is transferred to the supervisory level after some processing data will transfer to the plant level and finally, it reaches the company level.

Top MES (Manufacturing Execution System) Software used in Industry: –

| 1 | Inductive Automation |

| 2 | AVEVA |

| 3 | PLEX |

| 4 | IQMS |

| 5 | Infor |

| 6 | GE |

| 7 | SIEMENS |

| 8 | Emerson |

| 9 | Honeywell |

| 10 | Schnider Electric |

| 11 | WorkWise |

| 12 | Rockwell Automation |

| 13 | Wonderware |

| 14 | Epicor |

| 15 | Aiscrop |

MES Software explanation: –

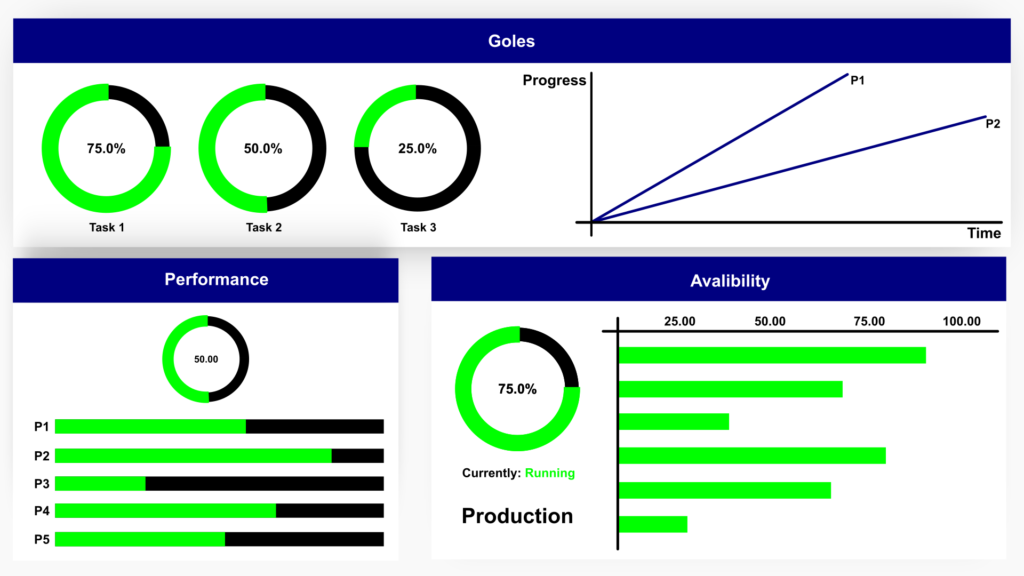

All MES software is a platform for any enterprise or company that is used to get all plant operational data and display meaningful and organized ways to get a whole overview of the plant.

This software is also used for the implementation of production planning data to plant computers to achieve production goals decided by companies.

Functionalities of MES software: –

- Material tracing from all over the plant

- Plant performance data analysis

- Increase Equipment Efficiency

- Connect to all Plant’s operational data

- Raw material handling

- Implementation of better-quality control

- Connect to ERP (Enterprise Resource Planning)

After seeing this functionality, you will get a whole overview of what MES software does for any enterprise available in the market.

EndNote –

This post is MES software used in higher levels of industrial automation for ease of manageability and traceability of plant operation according to company authority decisions.

After watching this post, you will get an overview of MES software and its basics of it. If you like this post then you may also like my other post about WHAT IS HMI (Human Machine Interface) AND IMPORTANCE.