Flow measurement is very important in the industry. In this article, I want to share with you all one guide that helps you to learn about Industrial Flow Measurement.

Introduction

There are multiple technologies available for the measurement of Flow. in this Artic I am covering all the basics of Industrial Flow Measurement and the Best Useful free resources.

Before we start learning about flow measurement, we have to learn about the terms below because it is very important.

- Accuracy

- Repeatability / Precision

- Rangeability / Turn Down Ratio

We one by one learn about these terms in simple language and examples for a better understanding of these terms.

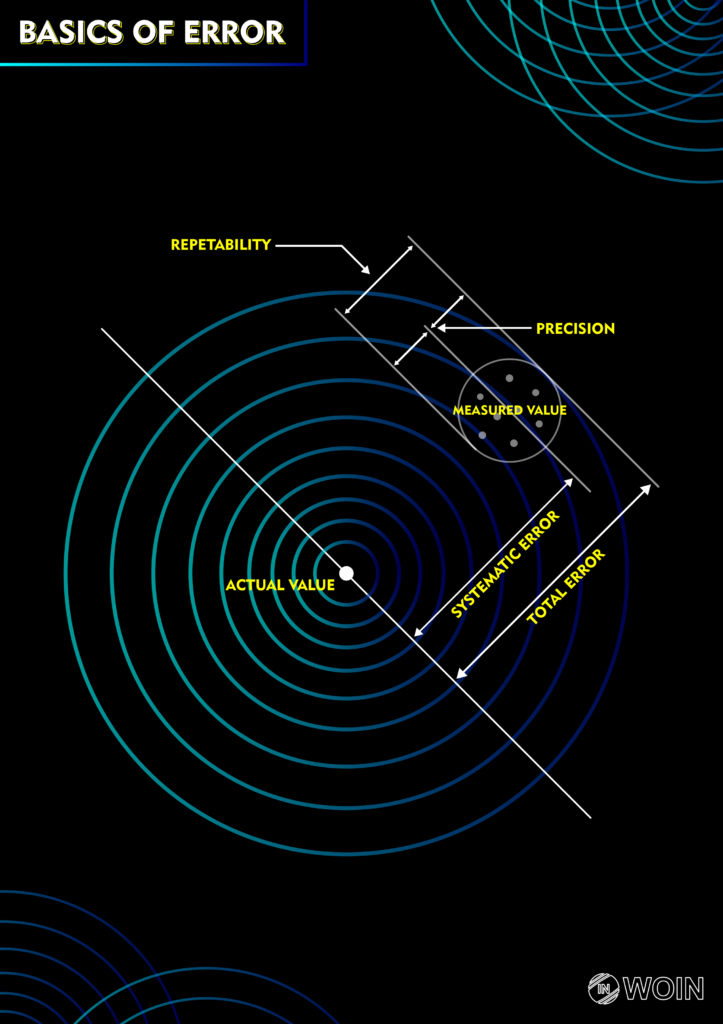

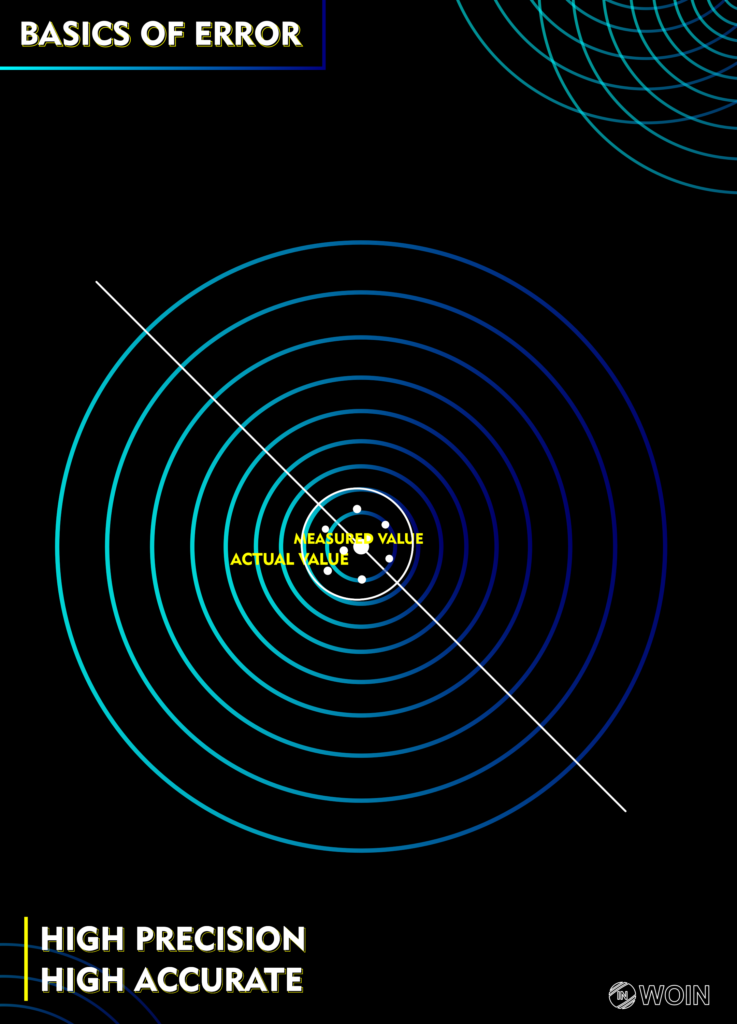

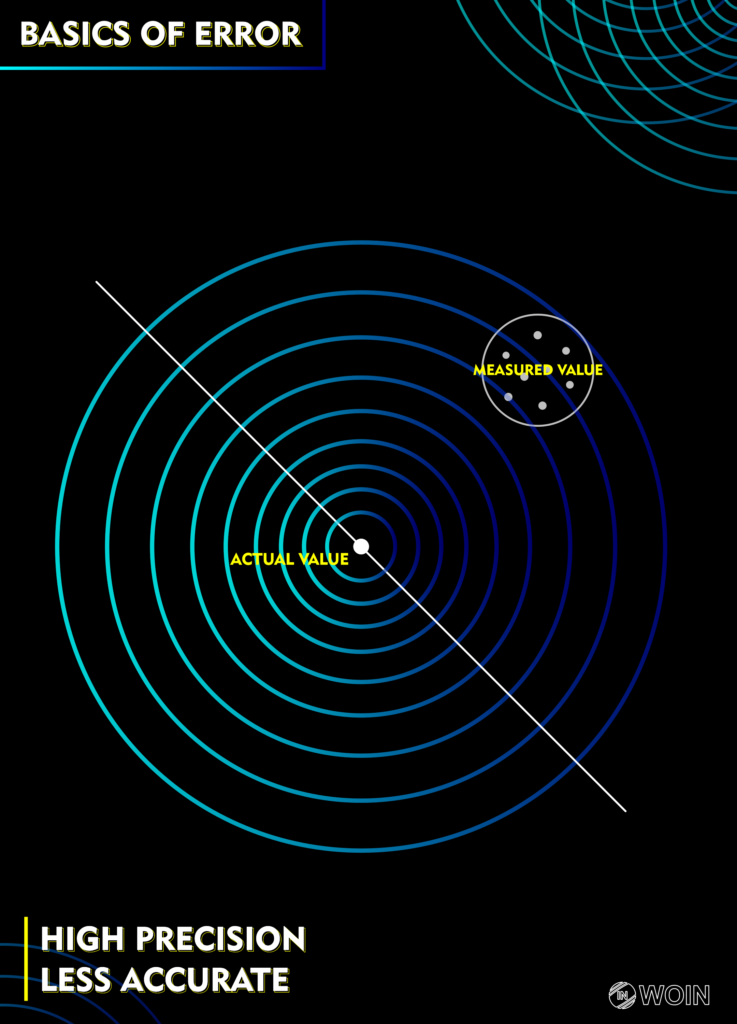

1. Accuracy

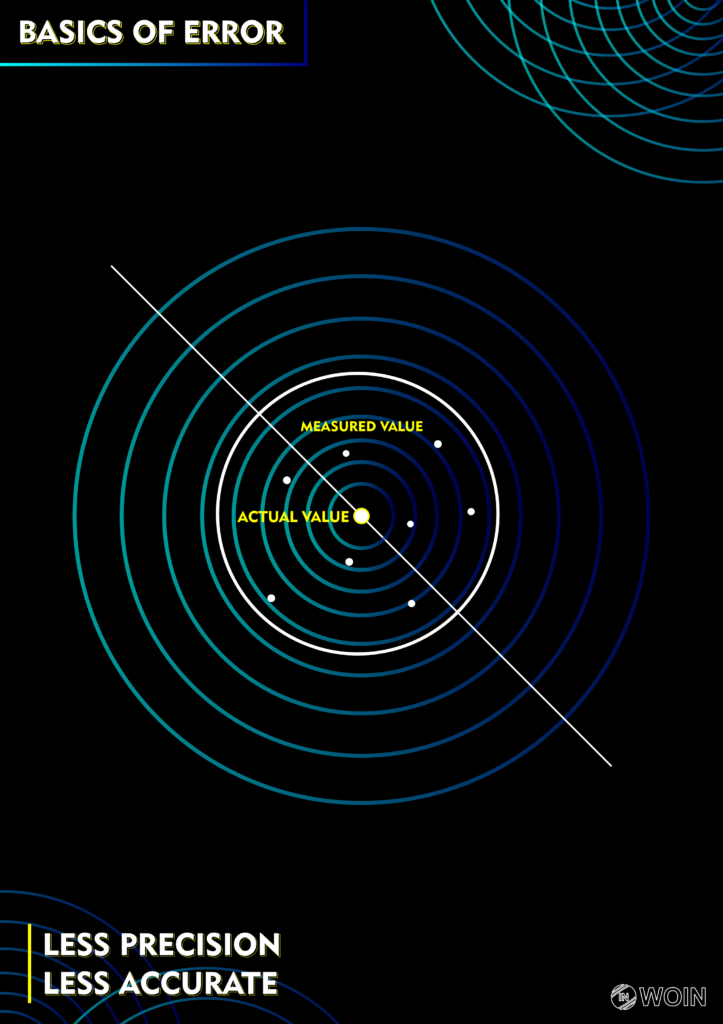

Accuracy is a very commonly used term in any instrument. As per definition, Accuracy shows the closeness of the measured value to the actual true value.

If the Measured value is close to the actual then the instrument is accurate. And if the Measured value is far from the actual value, then we conclude that the instrument is less accurate.

2. Repeatability / Reproducibility

Repeatability and Reproducibility are two aspects of Precision. In simple language Repeatability / Precision is defined as the Closeness of Measured to each other.

When we take repeat measurements in the same location with the same physical conditions then it is called Repeatability of Instruments.

Reproducibility is defined as repeat measurements with different locations with different physical conditions. You can visually that what is the difference between Accuracy and Precision.

3. Rangeability / Turndown Ratio

Rangeability or Turndown Ration is very important in flow measurement. In simple Language, Rangeability is defined as a Range of Flow that is measured within an accuracy tolerance. Rangeability is also represented in the “Turndown ration“.

Turndown ratio is defined as the ratio of Maximum flow and Min flow that the flow meter can measure.

Example: – A meter is Measure the Maximum flow of 100m3/d (100%) and the minimum flow of 10m3/d (Within specific accuracy tolerance like 0.5%) has 10:1 Rangeability or turndown.

STEP 1. Turndown Ratio = Maximum flow/ Minimum flow

STEP 2. Turndown Ratio = 100/10

STEM 3. Turndown Ratio = 10: 1

It shows that the meter measures the flow rate from 10m3/d to 100m3/d with 0.5% accuracy.

The meter may also provide better accuracy in a reduced measuring range if the meter provides 0.5% accuracy for 10:1 Turndown. It may also provide a tighter tolerance of 0.25% for a 3:1 turndown ratio.

I think now you have an idea about the basic terminology that you need to understand in flow measurement.

Types of Flow Measurement Technology

There are multiple flow measurement technologies available. And all technology has its advantages and disadvantages.

| Closed Pipe Flow Measurement | Velocity/ Force | Turbine |

| Vortex | ||

| CE and ME | ||

| Ultrasonic | ||

| Anemometer | ||

| Electromagnetic | ||

| Target | ||

| Positive Displacement | Nutating disk | |

| Oval Gear | ||

| Rotating Piston | ||

| Rotating Vane | ||

| Inferential | Variable Area Rotameter | |

| Orifice | ||

| Nozzle | ||

| Venturi | ||

| Dall | ||

| Pitot | ||

| Anubar | ||

| Elbow | ||

| Wedge | ||

| V Cone | ||

| Mass | Coriolis | |

| Thermal | ||

| Open Channel | Parshall Flume | |

| Weir | ||

Standards in Flow Measurement

Many organizations specially made worldwide acceptable standards for flow measurement.

Because Measurement of accurate flow is directly or indirectly connected with money. for example, oil and gas if it is not measured accurately then it shows a direct effect on the money factor.

1. American Gas Association (AGA)

AGA

| Sr. No. | Standards | Details |

|---|---|---|

| 1 | AGA Report No. 3 | Orifice Metering of Natural Gas |

| 2 | AGA Report No. 7 | Measurement of Gas by Turbine Meters |

| 3 | AGA Report No. 8 | Compressibility and Super-compressibility for Natural Gas and other Hydrocarbons. |

| 4 | AGA Report No. 9 | Measurement of Gas by Multipath Ultrasonic Meters |

2. American Petroleum Institute (API)

API

| Sr. No. | Standards | Details |

|---|---|---|

| 1 | Chapter 18 | Custody Transfer |

| 2 | Chapter 19 | Evaporation Loss Measurement |

| 3 | Chapter 20 | Allocation of Measurement of Oil and Natural Gas. |

| 4 | Chapter 21 | Flow Measurement Using Electronic Metering Systems |

| 5 | API RP 551 | Process Measurement Instrumentation |

| 6 | API 1101 | Measurement of Petroleum Liquid Hydrocarbons by Positive Displacement Meter |

| 7 | API 2534 | Measurement of Liquid Hydrocarbons by Turbine Meter Systems API Manual of Petroleum Measurement Standards – Measurement of Crude Oil by Coriolis Meter |

3. American Society of Mechanical Engineers (ASME)

ASME

| Sr. No. | Standards | Details |

|---|---|---|

| 1 | MFC-IM | Glossary of Terms Used in The Measurement of Fluid Flow in Pipes |

| 2 | MFC-2M | Measurement Uncertainty for Fluid Flow in Closed Conduits |

| 3 | MFC-3M | Measurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi |

| 4 | MFC-4M | Measurement of Gas Flow by Turbine Meters |

| 5 | MFC-5M | Measurement of Liquid Flow in Closed Conduits Using Transit-Time Ultrasonic Flowmeters |

| 6 | MFC-6M | Measurement of Fluid Flow in Pipes Using Vortex Flow Meters. |

| 7 | MFC-7M | Measurement of Gas Flow by Means of Critical Flow Venturi Nozzles |

| 8 | MFC-8M | Fluid Flow in Closed Conduits-Connections for Pressure Signal Transmissions Between Primary and Secondary Devices. |

| 9 | MFC-9M | Measurement of Liquid Flow in Closed Conduits by Weighing Method. |

4. American Society for Testing and Materials (ASTM)

ASTM

| Sr. No. | Standards | Details |

|---|---|---|

| 1 | D1070-85 | Standard Test Methods for Relative Density of Gaseous Fuels |

| 2 | D1072-90 | Standard Test Method for Total Sulfur in Fuel Gases |

| 3 | D1142-95 | Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature |

| 4 | D1826-94 | Standard Test Method for Calorific (Heating) Value of Gases in Natural Gas by Continuous Recording Calorimeter |

| 5 | D1945-96 | Standard Test Method for Analysis of Natural Gas by Gas Chromatography |

Learning Resources

1. Visual Learning through Video

I would like to thank the Endress+Hauser team for providing such amazing content on flow measurement.

1. Coriolis Flow Meter

The Coriolis Flow Measurement

2. Magnetic Flow Meter

3. Ultrasonic Flow Meter

4. Vortex Flow Meter

5. Thermal Mass Flow Meter

6. DP Flow Meter

7. DP Flow Meter Using Pitot Tube

2. Free Reference Books

ABB provides a free Handbook for Industrial Flow Measurement and you can download this free Handbook by clicking the download button.

EndNote

I hope now you have a basic understanding of industrial flow Measurement and that all the resources I shared become helpful to you.

If you like this article you can also like my previous article on Magnetics flowmeter | A complete Guide.