Introduction: –

In this post, I will give you some tips about How to Upgrade your Standard HMI to High-Performance HMI?

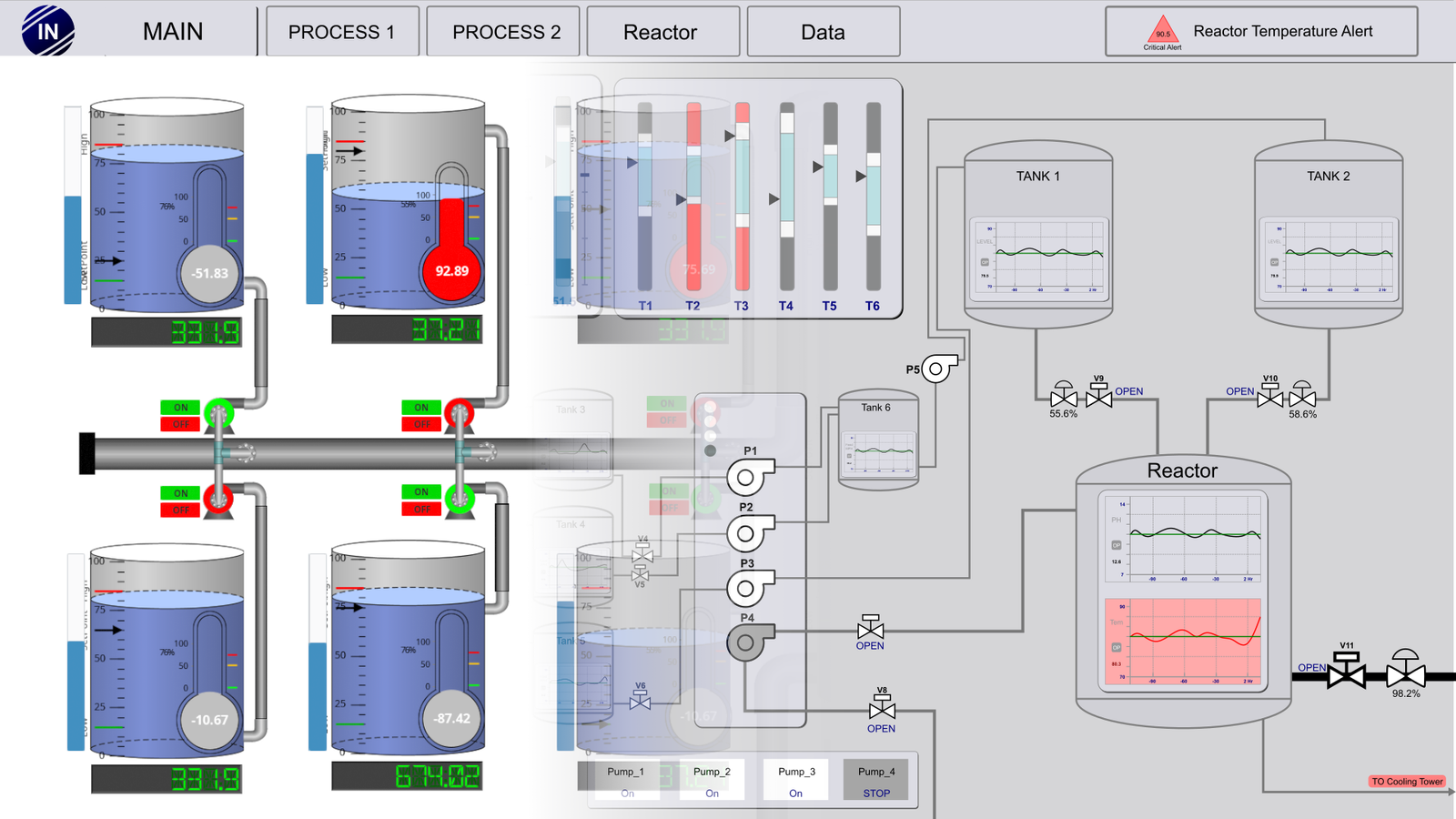

HMI (Human Machine Interface) is a very important part of any industrial automation not because it provides a graphical representation of all plant processes but also indirectly responsible for improving plant efficiency by providing proper visualizes to plant operators.

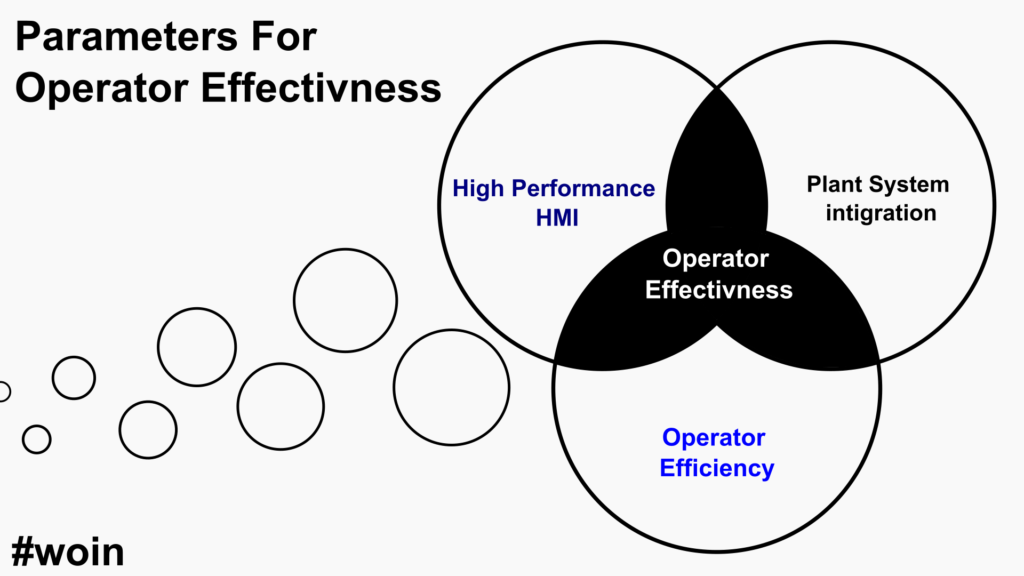

Parameters That affect Operator Effectiveness

- High-Performance HMI

- Operator Efficiency

- Plant System Integration

- Working environment

Now most companies are adopting High-Performance HMI to improve plant efficiency and performance by giving optimal graphical representation to operators to increase maximum Operator effectiveness.

That’s why ISA (International Society of Automation) introduced standard ISA101 for High-Performance HMI.

So, in this post, I will give you step-by-step guidelines for how to switch from your traditional HMI to a High-Performance HMI to improve plant productivity and performance.

Design Fundamental

Before you start HMI design you must have basic knowledge of fundamental design.

Design knowledge will help you to create a stunning HMI screen for your industrial application.

Topics that are you consider before designing your HMI screen

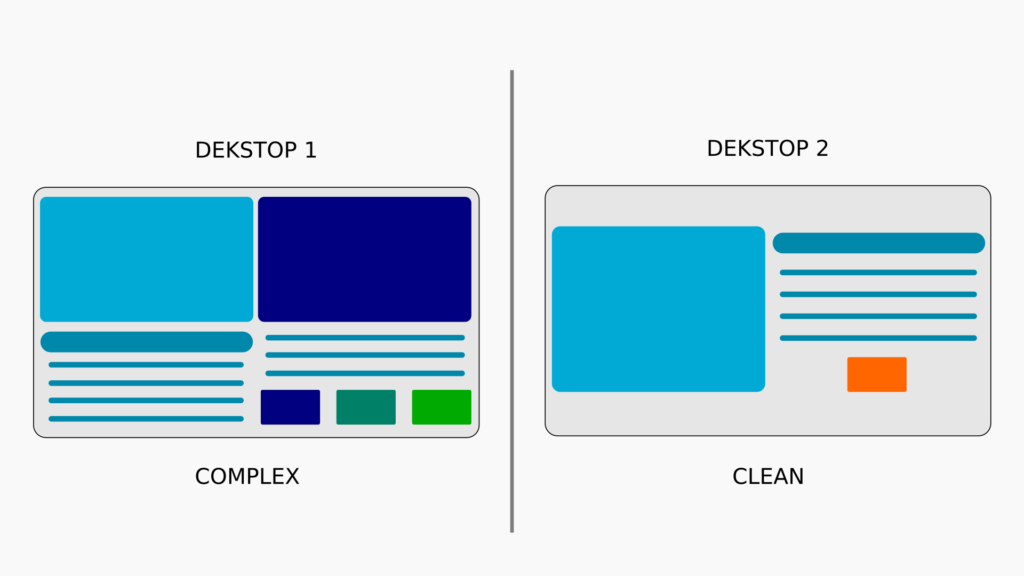

- Cognitive Load

Cognitive load is all about the complexity of your HMI design. If your design is too complex then it will be considered a high cognitive load and it will directly lead to a poor user experience.

- Responsiveness

Responsiveness is defined as how your design is looked at in different screen sizes. Responsive HMI design helps direct access of HMI on different mobile screens.

- Visual Hierarchy

It is all about the arrangement of objects in your HMI according to create the best and cleanest design experience for the user or operator.

- Typography

Typography is all about how to use text elements in HMI design. By proper placing of text, the element will help users to recognize the information and readability they want.

- Color

It is a very important part of any design, and it is used to describe meaning without any signal word.

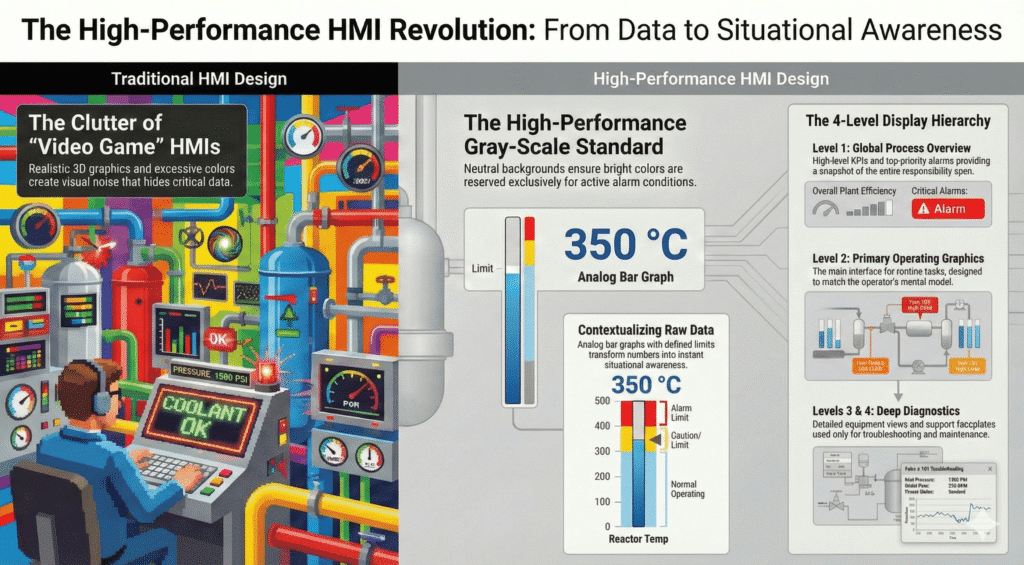

High-Performance HMI is all about using some limited color for the highest operator effectiveness.

Tips for How to upgrade your standard HMI

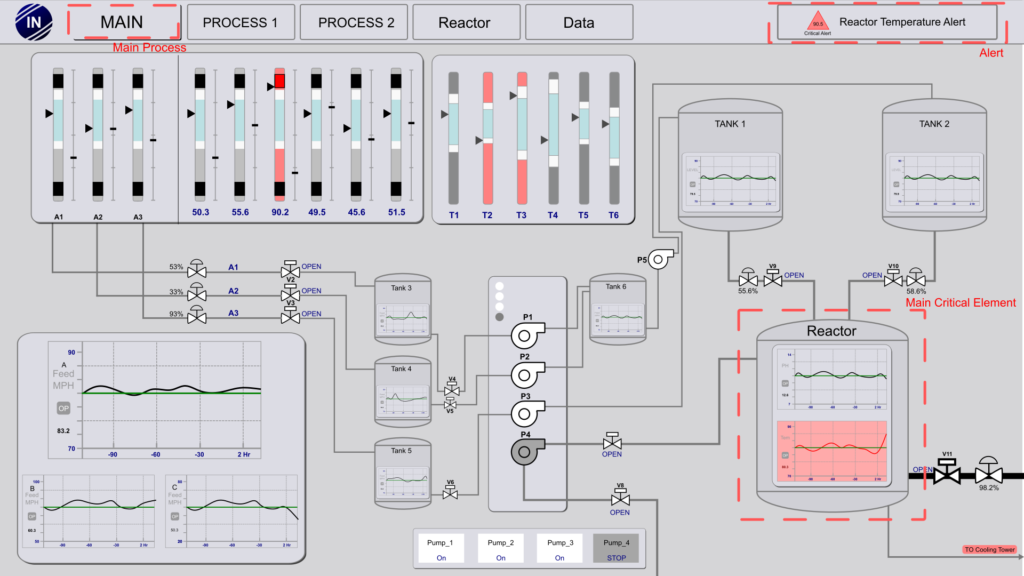

1. Size and Location of Plant Graphical Elements

The size and location of plant graphical element is a very important part of high-performance HMI and thesize and shape of plant graphic element are directly related to operator efficiency.

These are some rules that you can apply to your old HMI for Upgrading to High-Performance HMI.

- Choose the size of the plant graphical element according to how critical the element is, I prefer the set size of critical element big compare to other elements. That will help operators directly focus on this critical element if any abnormal situation happens.

- Display Main Process on the First page of HMI

- Display Alarm Activity on the Right side corner of the HMI screen, And Display the Active alarm in the Blinking state that will help to bring operator attempt as quickly as possible.

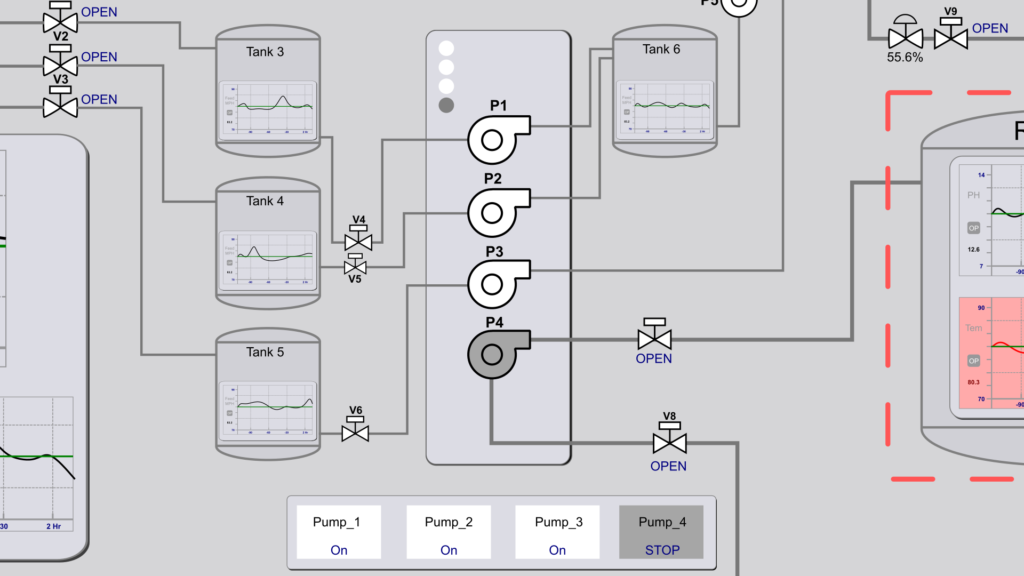

2. Replace all your plant graphical elements with high-performance graphics elements.

Plant graphical elements will be different according to what type of HMI design software you use. For example, the image of the tank will not be the same in any HMI software.

But the high-performance symbol of the tank is the same for every application and it will display below how the tank image will differ in standard HMI and High-performance HMI.

As you can see, in high-performance HMI tank symbol looks more effective than the Standard HMI tank symbol displayed on the right-hand side images.

This is not only applicable to tanks; it will be applicable to all plant elements that are displayed on the HMI screen.

High-performance HMI pipes that connect one element to another element will be directly represented by Straight lines instead of messy graphical-type pipes.

3. Select the Right colors for your HMI screen

It is a very important part of any HMI display. If HMI uses more ineffective colors, then the operator will stick to distinguishing what is happening in plants and it is very inefficient.

This is an example of how to set the right color for different element displays in the HMI screen according to the High-performance HMI standards.

- Take Background color of HMI is light gray

- Elements that are on will display in White color

- Elements that are off will display in Dark gray color

- Display process connection lines with dark gray color

- The alarm will display red, green, and yellow colors

- choose black color for the Historical Trend

- Display setpoint with green color

- Represent safe operation range using white color

- Display High and low range with red color

- Display process numbers and values in dark colors like black, dark blue

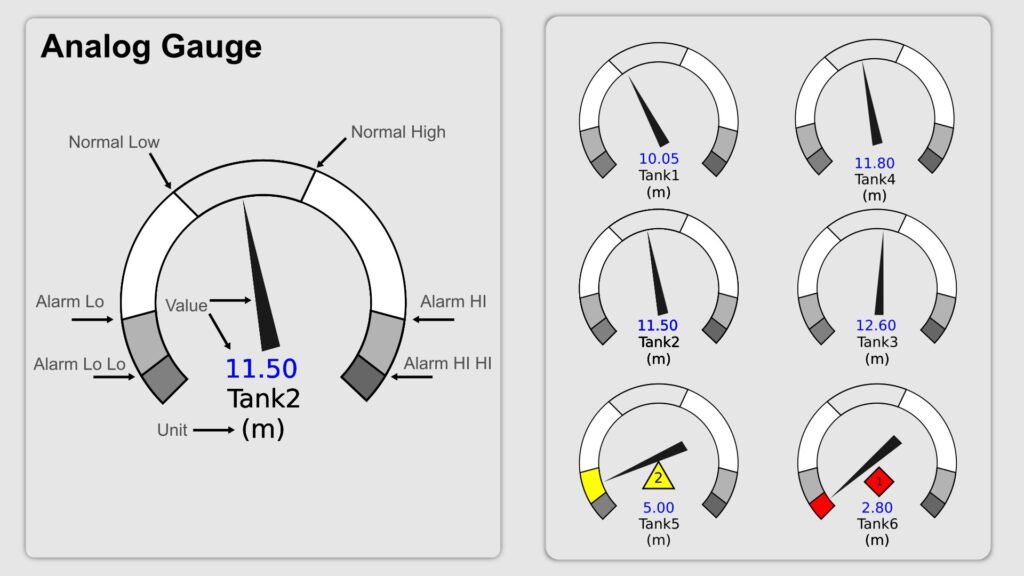

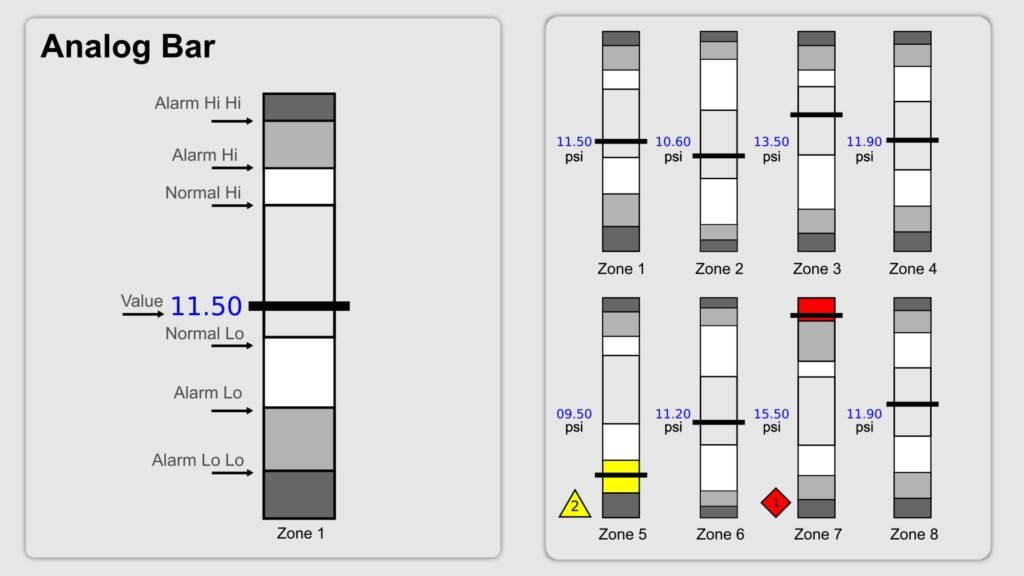

Graphical Element: –

Humans are easily finding pattern changes. Instead of displaying the numerical value on HMI try to put an analog Gauge that will grab the operator’s attention easily when under abnormal conditions.

Resources: –

For a detailed guide, I will recommend you to watch the REALPARS video series on High-Performance HMI. It will help you to get in-depth information on this topic.

And I also recommended you to see the ISA101 standard on High-Performance HMI by becoming an ISA member if you have not yet.

EndNote: –

These are all these tips and tricks you can follow for upgrading your standards HMI to high-performance HMI and enhancing operator efficiency and plant safety.

I will regularly be updated whenever I get more information about this topic to thank you.

If you have any suggestions then comment below or send mail to contact@worldofinstrumentation.com

If you like this post then you will check out our last post on how 5g technology will evolve industrial automation and transform industrial communication.