Introduction: –

OPC-UA is an open standard cross-platform communication protocol in this post you can find What is OPC-UA | How is it used in the industry?

The full form of OPC-UA is Open Platform Communication- Unified Architecture

it is a communication protocol that is specially designed to remove industrial communication complexity and transfer data to any Level of automation whenever needed.

Now data transfer between levels of automation is easy by using OPC-UA.

OPC Foundation is Handel and Maintain OPC protocol and worldwide automation member that designs and develops hardware and Software on OPC protocol.

Characteristics of OPC-UA: –

- Cross-Platform and ready to communicate on the internet

- complex information model

- Security

- Service

How is it used in industry?

How does OPC-UA work?

OPC-UA is based on client and server applications. The server is getting data from PLC and storing it and transferring data to the client.

By using the OPC-UA protocol client can Access Real-time data, Monitoring of alarms, and access historical data from the server.

But as a student or beginner, you probably have one question in mind what is client and server? so let me explain simply.

What are Client and Server?

In OPC-UA Client and server is just a piece of code that is implemented on a system like a computer, PLC, and other hardware.

Using some coding you will be able to create an OPC server and client on the same computer. for learning, there is Third-party software is available for creating OPC servers and clients on your computer.

Nowadays all the latest PLCs come with OPC-UA features and it will make IIOT possible.

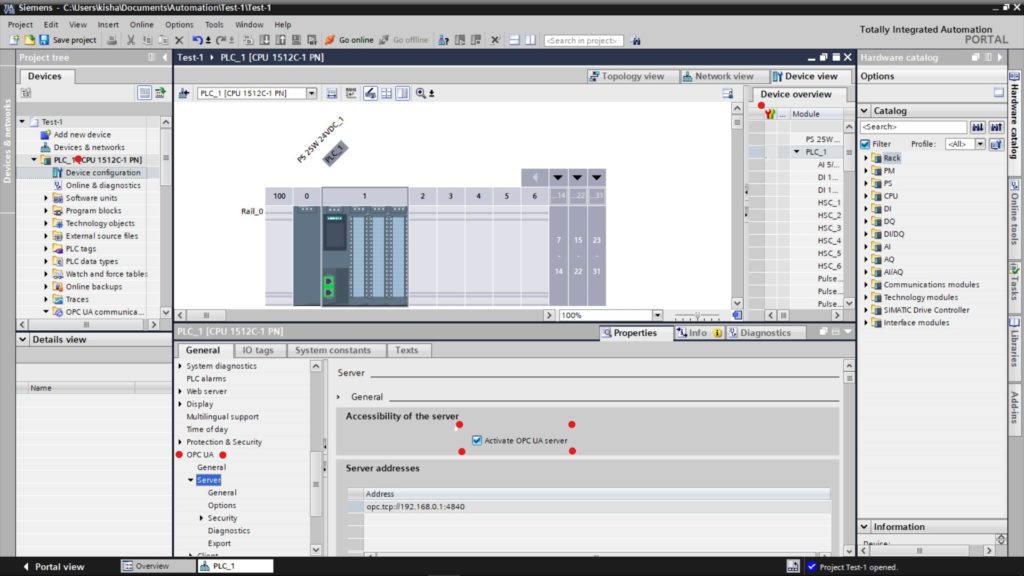

With the right software license, you will be able to access the OPC-UA features available in PLC. As you can see from the below image of siemens TIA Portal V16 OPC UA features.

Allan Bradley PLC and other plc also come with OPC-UA built-in features so you can directly access data by using the OPC client.

Some PLC manufacturers charge extra money for adding OPC-UA features to their PLC. Another third-party company is also designing software add-ons and drivers for adding OPC features in PLC Ex-Matrikon.

Mainly in siemens PLC, OPC clients and servers are communicating using profit and industrial Ethernet.

How to Configure OPC-UA in PLC?

In This post, I am giving you an example of how OPC is used in siemens plc.

For starting communication between the OPC-UA server and the client you need to enter the server address into the client software. format of server address is given below,

OPC.tcp://Device IP:Port number

After the server address is entered into the client software you have to give security information if a security layer is created in servers.

Without an id and password, clients can’t get the data from the server and that is the advantage of the OPC-UA protocol.

dedicated Manu is giving in server settings for configuring the level of security. Users can also create server certification for validation and verification of servers connected to clients.

- No security

- 1)Basic 128 sign

- 2)Basic 128 sign & encrypt

- 3)Basic 256 sign

- 4)Basic 256 sign & encrypt

- 5)Basic 256ha256 sign

- 6)Basic 256ha256 sign & encrypt

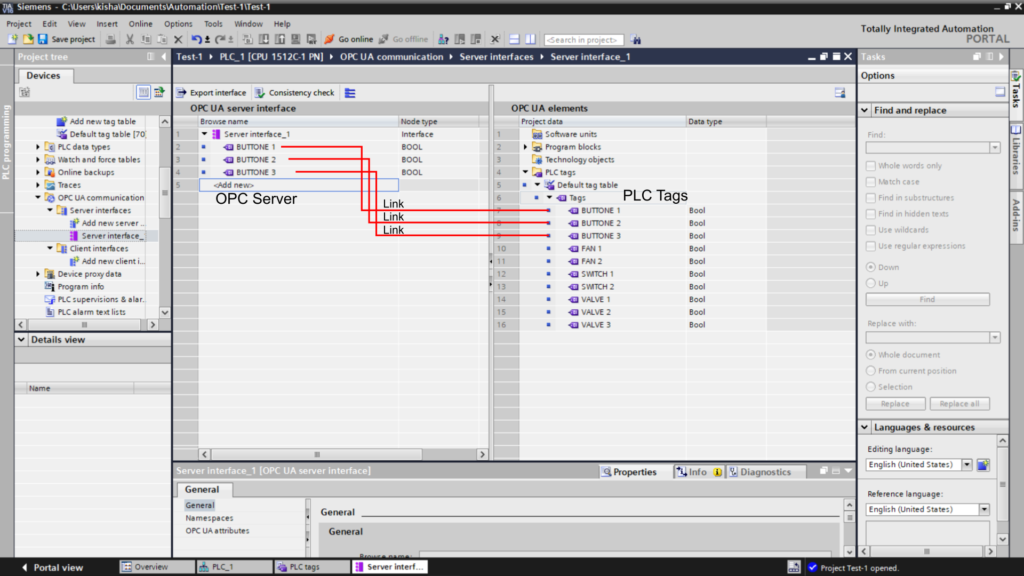

After connection, you have the option to drag the tag to the OPC server for which tag data is transmitted to the OPC server in Siemens TIA Portal V16.

you can find this option in other software also like Studio 5000, PLCNext, etc

By using OPC-UA you can store data directly to cloud storage and access data from anywhere in the world.

EndNote: –

So, this is all about this communication protocol and how it will be used to reduce data communication complexity and platform dependency. I hope you find some new knowledge about this protocol.

For this post, I will only discuss the instrumentation point of view if you want to get deeper knowledge than know IT field.

If you find this post interesting then please check out our previous post on how to upgrade your old HMI into High-Performance HMI

[…] OPC-UA communication standard | How it is use in industry? […]